Mga produkto

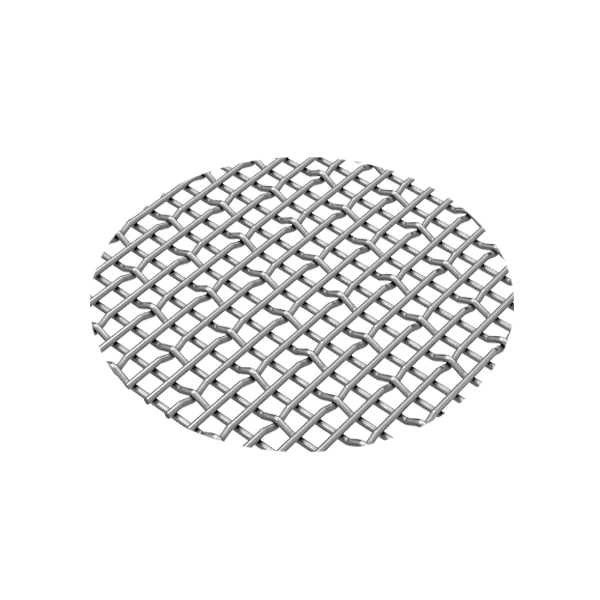

Pinagtagpi na Wire Mesh Para sa Pagsasala, Pag-screen, Pagtanggol at Pagpi-print

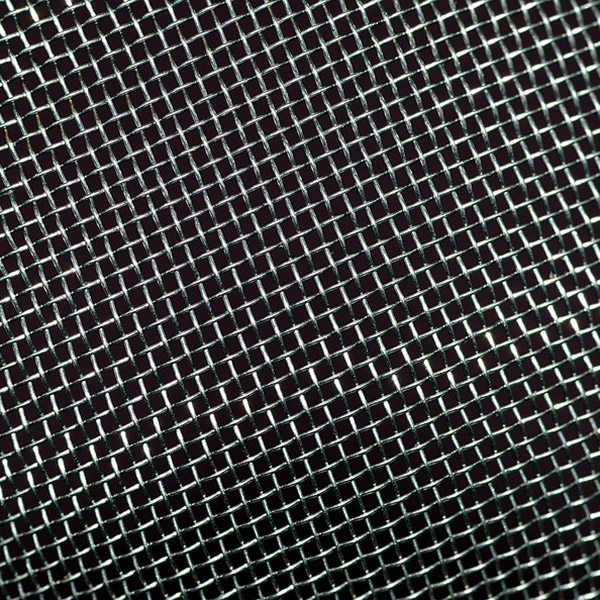

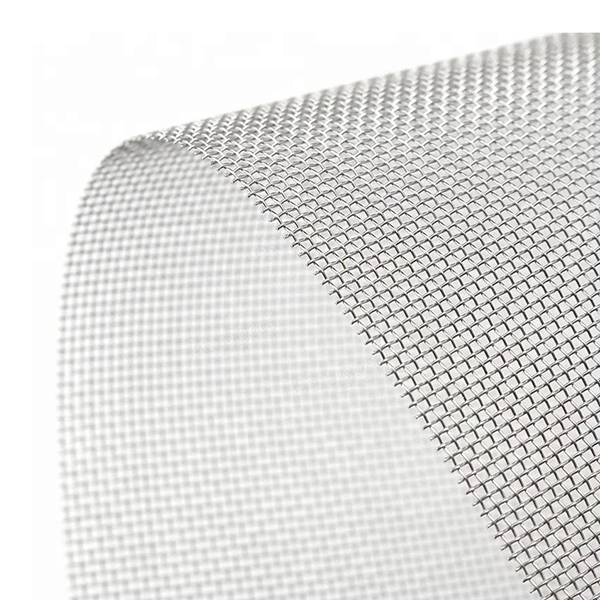

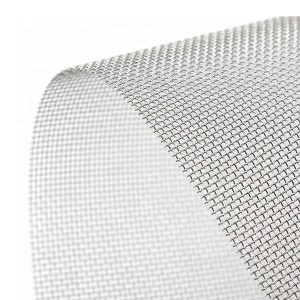

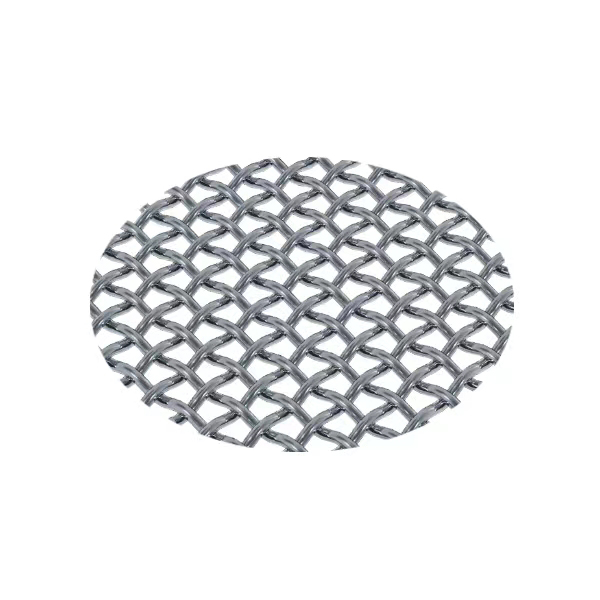

Plain Weave

Ang pinakasimpleng at pinakakaraniwang ginagamit na uri na may mga parisukat na bakanteng. Ito ay hinahabi sa pamamagitan ng pagpapalit-palit ng weft wire sa ibabaw at sa ilalim ng warp wire at pinahihintulutan ang positibong kontrol sa laki ng mga materyales na i-screen o i-filter.

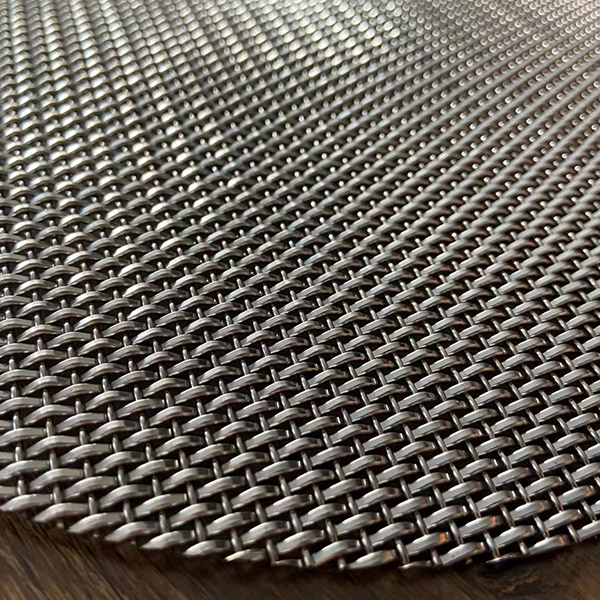

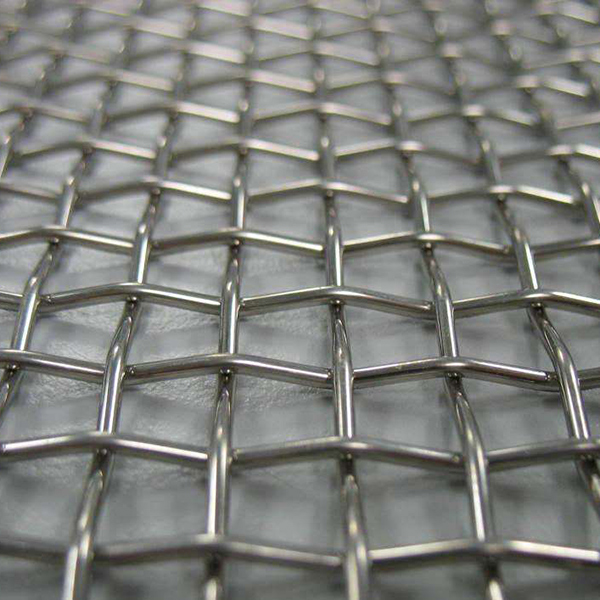

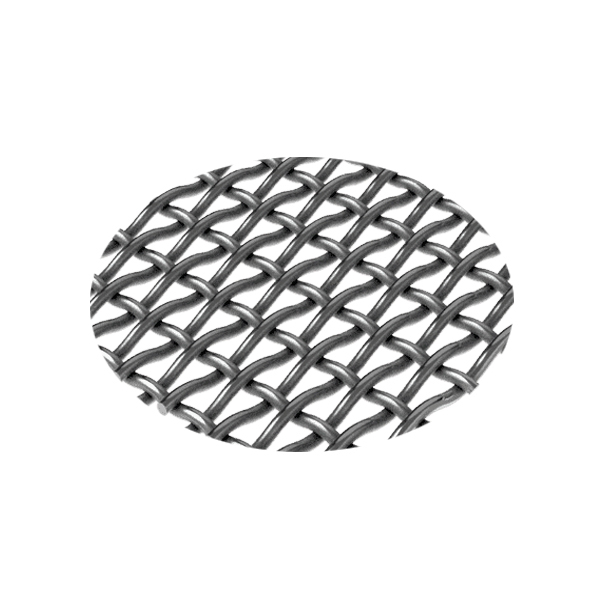

Twill Weave

Ang bawat weft wire ay salit-salit na dumadaan sa ibabaw at sa ilalim ng 2 warp wire, na pasuray-suray sa magkakasunod na warps. Ito ay ginagamit kung saan ang pinong mesh ay dapat magdala ng mabigat na karga.

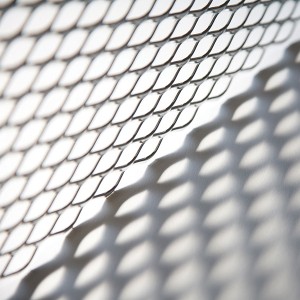

Oblong Weave

Kilala rin bilang malawak na paghabi, mas maganda itong ginawa sa plain weave na may opening ratio (haba/lapad) na 3:1. Posible ang iba pang mga ratios. Available din ang triple warp weave para magbigay ng malalaking bukas na lugar. Ito ay ginagamit para sa vibrating sieving screen o iba pang architectural application.

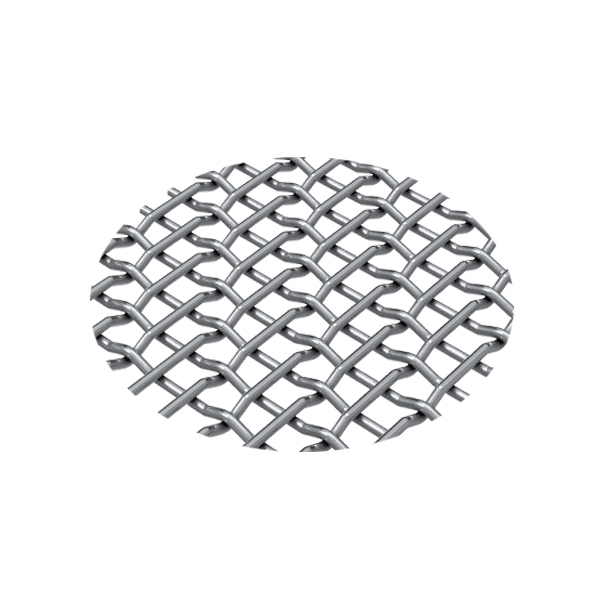

3-Heddle Weave

Sa ganitong uri ng paghabi, ang bawat warp wire ay salit-salit na dumadaan pataas at pababa sa bawat isa at dalawang weft wire nang salit-salit. Katulad nito, ang bawat weft wire ay salit-salit na pataas at pababa ng bawat isa at dalawang warp wire. Ito ay malawakang ginagamit sa mga filter ng industriya, mga disc ng filter at mga silindro ng filter para sa pagsasala.

5-Heddle Weave

Sa ganitong uri ng paghabi, ang bawat warp wire ay salit-salit na pataas at pababa sa bawat isa at apat na weft wire at vice versa. Nagbibigay ito ng hugis-parihaba na pagbubukas at nag-aalok ng mataas na rate ng daloy. Ito ay malawakang ginagamit sa pagsasala ng mga industriya ng petrolyo at kemikal.

Pagtutukoy

Materyal:Hindi kinakalawang na asero, SS304, SS316, SS316L, SS201, SS321, SS904, atbp. Brass, Copper, Nickel, silver, monel alloy, inconel alloy, hastely alloy, iron chrome aluminum alloy, iron wire carbon steel tulad ng 65mn, galvanized wire, atbp.

Wire diameter:0.02–2 mm

Bilang ng mesh:2.1–635 mesh

Lapad ng siwang:0.02–10.1 mm

Buksan ang screening area:25% – 71%

| Mesh Sinabi ni Count | Wire Diameter (d) | Aperture Width (w) | Bukas Screening Aya | Mpuwet | Aperture Quantities 1 cm2 |

| Hindi. | mm | mm | % | kg/m2 | |

| 635 | 0.02 | 0.02 | 25 | 0.127 | 62500 |

| 508 | 0.025 | 0.025 | 25 | 0.159 | 40000 |

| 450 | 0.027 | 0.03 | 27.7 | 0.162 | 31388 |

| 400 | 0.027 | 0.036 | 32.7 | 0.147 | 24800 |

| 363 | 0.03 | 0.04 | 32.7 | 0.163 | 20424 |

| 325 | 0.035 | 0.043 | 30.4 | 0.199 | 16372 |

| 314 | 0.036 | 0.045 | 30.9 | 0.203 | 15282 |

| 265 | 0.04 | 0.056 | 34 | 0.212 | 10885 |

| 250 | 0.04 | 0.063 | 37.4 | 0.197 | 9688 |

| 210 | 0.05 | 0.071 | 34.4 | 0.262 | 6836 |

| 202 | 0.055 | 0.071 | 31.8 | 0.305 | 6325 |

| 200 | 0.053 | 0.074 | 34 | 0.281 | 6200 |

| 200 | 0.05 | 0.08 | 37.9 | 0.244 | 6200 |

| 188 | 0.055 | 0.08 | 35.1 | 0.285 | 5478 |

| 170 | 0.055 | 0.094 | 39.8 | 0.258 | 4480 |

| 150 | 0.071 | 0.1 | 34.6 | 0.366 | 3488 |

| 154 | 0.065 | 0.1 | 36.7 | 0.325 | 3676 |

| 200 | 0.03 | 0.1 | 61 | 0.078 | 6200 |

| 150 | 0.06 | 0.11 | 41.9 | 0.269 | 3488 |

| 130 | 0.08 | 0.112 | 34 | 0.423 | 2620 |

| 140 | 0.06 | 0.12 | 44.4 | 0.254 | 3038 |

| 120 | 0.09 | 0.12 | 32.7 | 0.49 | 2232 |

| 124 | 0.08 | 0.125 | 37.2 | 0.396 | 2383 |

| 110 | 0.09 | 0.14 | 37.1 | 0.447 | 1876 |

| 106 | 0.1 | 0.14 | 34 | 0.529 | 1742 |

| 100 | 0.11 | 0.14 | 31.4 | 0.615 | 1550 |

| 100 | 0.1 | 0.15 | 36 | 0.508 | 1550 |

| 100 | 0.1 | 0.16 | 37.9 | 0.488 | 1550 |

| 91 | 0.12 | 0.16 | 32.7 | 0.653 | 1284 |

| 80 | 0.14 | 0.18 | 31.6 | 0.784 | 992 |

| 84 | 0.1 | 0.2 | 44.4 | 0.42 | 1094 |

| 79 | 0.12 | 0.2 | 39.1 | 0.572 | 967 |

| 77 | 0.13 | 0.2 | 36.7 | 0.65 | 919 |

| 46 | 0.15 | 0.4 | 52.9 | 0.505 | 328 |

| 70 | 0.1 | 0.261 | 52 | 0.354 | 760 |

| 65 | 0.1 | 0.287 | 54.6 | 0.331 | 655 |

| 61 | 0.11 | 0.306 | 53.6 | 0.307 | 577 |

| 56 | 0.11 | 0.341 | 56.8 | 0.283 | 486 |

| 52 | 0.12 | 0.372 | 56.8 | 0.374 | 419 |

| 47 | 0.12 | 0.421 | 60.3 | 0.342 | 342 |

| 42 | 0.13 | 0.472 | 61.2 | 0.306 | 273 |

| Mesh Sinabi ni Count | Wire Diameter (d) | Aperture Width (w) | Bukas Screening Aya | Mpuwet | Aperture Quantities 1 cm2 |

| Hindi. | mm | mm | % | kg/m2 | |

| 2.1 | 2 | 10.1 | 69.7 | 3.95 | 0.68 |

| 3 | 1.6 | 6.87 | 65.8 | 3.61 | 1.4 |

| 3.6 | 2 | 5.06 | 51.3 | 6.77 | 2.01 |

| 4 | 1.2 | 5.15 | 65.8 | 2.71 | 2.48 |

| 4 | 1.6 | 4.75 | 56 | 4.81 | 2.48 |

| 5 | 1.2 | 3.88 | 58.3 | 3.38 | 3.88 |

| 5 | 1.6 | 3.48 | 46.9 | 6.02 | 3.88 |

| 6 | 0.9 | 3.33 | 62 | 2.28 | 5.58 |

| 6 | 1.2 | 3.03 | 51.3 | 4.06 | 5.58 |

| 8 | 0.7 | 2.48 | 60.8 | 1.84 | 9.92 |

| 8 | 1 | 2.18 | 46.9 | 3.76 | 9.92 |

| 8 | 1.2 | 1.98 | 38.7 | 5.41 | 9.92 |

| 10 | 0.4 | 2.14 | 71 | 0.75 | 15.5 |

| 10 | 0.5 | 2.04 | 64.5 | 1.18 | 15.5 |

| 10 | 0.6 | 1.94 | 58.3 | 1.69 | 15.5 |

| 12 | 0.4 | 1.72 | 65.8 | 0.9 | 22.32 |

| 12 | 0.5 | 1.62 | 58.3 | 1.41 | 22.32 |

| 12 | 0.65 | 1.47 | 48 | 2.38 | 22.32 |

| 14 | 0.5 | 1.31 | 52.5 | 1.65 | 30.38 |

| 16 | 0.4 | 1.19 | 56 | 1.2 | 39.68 |

| 16 | 0.5 | 1.09 | 46.9 | 1.88 | 39.68 |

| 18 | 0.4 | 1.01 | 51.3 | 1.35 | 50.22 |

| 18 | 0.5 | 0.91 | 41.7 | 2.12 | 50.22 |

| 20 | 0.3 | 0.97 | 58.3 | 0.85 | 62 |

| 20 | 0.35 | 0.92 | 52.5 | 1.15 | 62 |

| 20 | 0.4 | 0.87 | 46.9 | 1.5 | 62 |

| 20 | 0.5 | 0.77 | 36.8 | 2.35 | 62 |

| 24 | 0.36 | 0.7 | 43.5 | 1.46 | 89.28 |

| 30 | 0.25 | 0.6 | 49.7 | 0.88 | 139.5 |

| 30 | 0.3 | 0.55 | 41.7 | 1.27 | 139.5 |

| 35 | 0.25 | 0.5 | 44.4 | 1.03 | 189.9 |

| 40 | 0.2 | 0.44 | 46.9 | 0.75 | 248 |

| 40 | 0.25 | 0.39 | 36.8 | 1.18 | 248 |

| 45 | 0.25 | 0.31 | 31 | 1.32 | 313.88 |

| 50 | 0.18 | 0.33 | 41.7 | 0.76 | 387.5 |

| 50 | 0.2 | 0.31 | 36.8 | 0.94 | 387.5 |

| 50 | 0.23 | 0.28 | 29.9 | 1.24 | 387.5 |

| 60 | 0.12 | 0.3 | 51.3 | 0.41 | 558 |

| 60 | 0.16 | 0.26 | 38.7 | 0.72 | 558 |

| 60 | 0.18 | 0.24 | 33 | 0.91 | 558 |

| 70 | 0.12 | 0.24 | 44.8 | 0.48 | 759.5 |

| 80 | 0.12 | 0.2 | 38.7 | 0.55 | 992 |

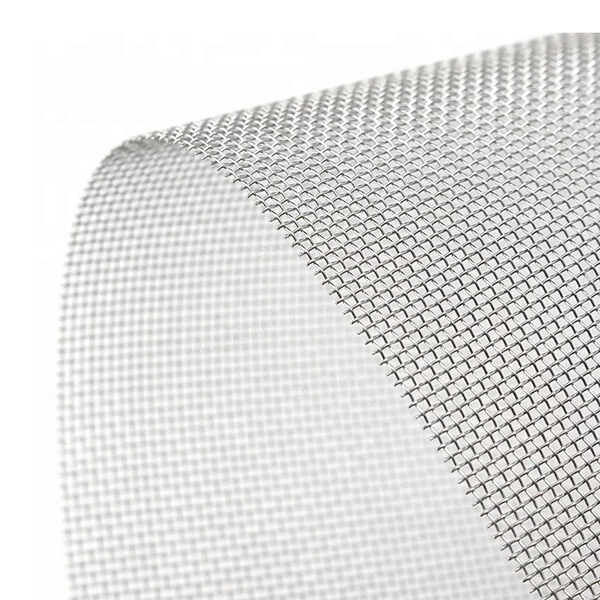

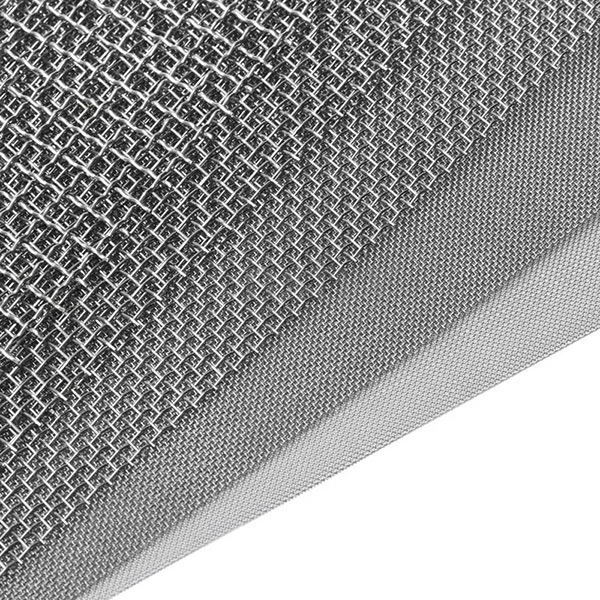

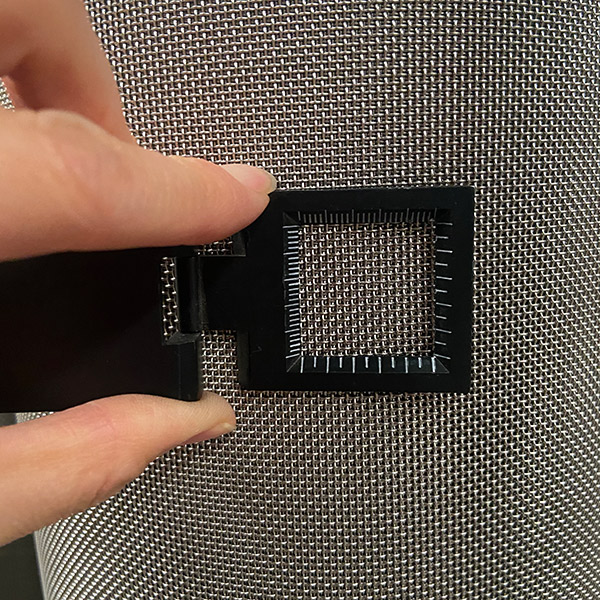

Pagpapakita ng Produkto